Laser Cladding Services

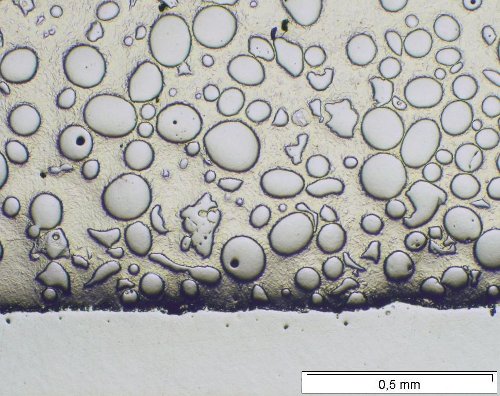

Laser Cladding is an alternative to traditional welding and thermal spray. This technology is similar to thermal spray in that it has an energy source to melt the feed stock that is being applied to a substrate. Where it differs is that it uses a concentrated laser beam as the heat source and it melts the substrate that the feed stock is being applied to. This results in a metallurgical bond that has superior bond strength over thermal spray. Additionally the resulting coating is 100% dense with no voids or porosity.

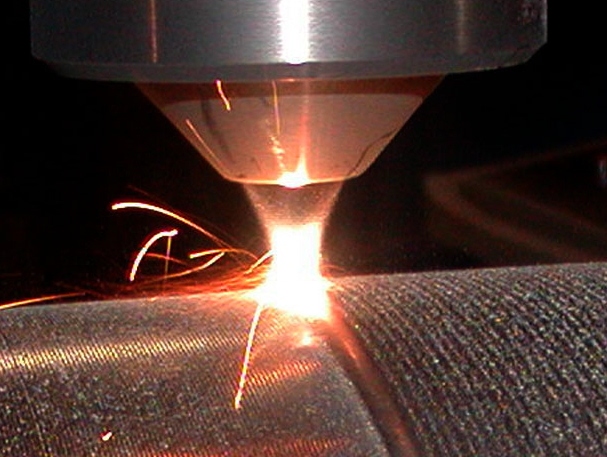

Laser Beam melting the substrate and feed stock powder

Metallographic photo of laser cladding

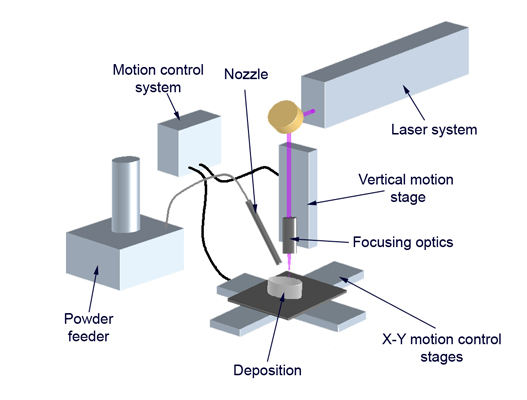

The basic system is made up of a laser to generate the beam, a set of optics to direct and focus the beam, a powder feeder, and a part manipulator. The laser and optics stay stationary and the part is moved in relationship to the laser. The laser cladding systems are fully automated providing precise control of the coating (cladding) process.

Typical Laser cladding system layout

From Wikipedia, the free encyclopedia

One of the advantages of the laser cladding process is the concentrated beam of energy from the laser. It can be focused and concentrated to a very small area and keeps the heat effected zone of the substrate very shallow. This minimizes the chance of cracking, distorting, or changing the metallurgy of the substrate. Additionally the lower total heat minimizes the dilution of the coating with material from the substrate.

Coating thicknesses can reach .125″ (3.1mm) with carbides in one pass and can go to any thickness with other materials and multiple passes.

Because the feed stock is a powder, there is a large variety of materials available including pure metals, alloys, or carbides. We have worked extensively with Inconel and Stellite alloys on a wide assortment of oil field applications.

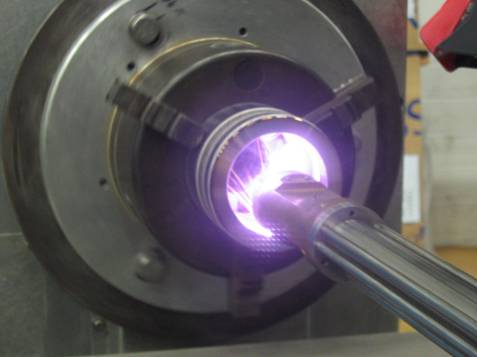

Inner Diameter Laser Welding Tooling

Please give us a call to see how we might be able to help you with your coating needs.

Call 724-229-5791